What is UV Coating in Printing?

In today’s fast-moving and visually focused world, packaging is more than just a container for products. It shares a brand’s story, grabs attention, and shows the quality customers can expect. As brands compete to win loyal customers and stand out on store shelves, UV coating has become a powerful tool in packaging design.

This special finishing technique uses ultraviolet light to dry a clear, protective layer, creating a shiny or smooth finish that makes the packaging look premium and unforgettable.

UV coating stands for Ultraviolet Coating. It is a special shiny or matte finish added to printed paper to make it look fancy. Think of it as a transparent layer that protects your paper while making it beautiful.

Furthermore, Ultraviolet light is the secret behind the magic of UV coating. It works so quickly to dry and harden the liquid layer. Without UV light, the coating would take a long time to dry, and it would not look as good.

The History and Evolution of UV Coating in Printing

A long time ago, printing was simple. People used basic inks and paper to create books, posters, and cards. Over time, they wanted prints to look more colorful and last longer. This is when UV coating started to become popular.

In the 1970s, people found out that using special liquid and ultraviolet (UV) light could make printed things shiny and strong. This was a big change! The UV light would dry the liquid quickly, making it stick to the paper and create a glossy layer. At first, only big companies could use UV coating because it was expensive and hard to do.

Later, in the 1990s, technology got better. Machines for UV coating became smaller and easier to use. More people could afford them, so UV coating started showing up on magazines, book covers, and even greeting cards. This made prints look fancy and helped protect them from scratches.

Now, UV coating is everywhere. It is used to make business cards, wedding invitations, and even packaging look shiny and professional. Today, companies can even choose between different types of UV coating, like matte or glittery finishes, to match their style.

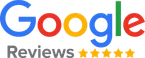

Different Types of UV Coating

There are different kinds of UV coatings to match your needs. Here are the most popular ones:

Glossy UV Coating

This type makes the paper super shiny, like a mirror. It is perfect for things like magazines or photo books because it makes colors pop.

Matte UV Coating

Matte coating does not shine. Instead, it gives the paper a smooth and elegant look. People use it for wedding invitations or business cards to make them look classy.

Spot UV Coating

Spot UV is like adding shine to only one part of the paper, not the whole thing. For example, you can make just your logo or name shiny while the rest stays plain.

Textured UV Coating

This type makes the paper feel bumpy or raised. It is fun to touch and is used for creative designs.

Advantages of UV Coating

Makes Colors Pop

UV coating adds a shiny or smooth finish that makes colors look brighter and more vibrant. This makes your designs stand out.

Protects the Paper

the coating creates a strong shield that protects your printed items from scratches, dirt, and water. However, this helps your work last longer.

Feels Smooth and Fancy

When you touch UV-coated paper, it feels very smooth and premium. Significantly, this gives your project a high-quality feel.

Dries Quickly

Thanks to UV light, the coating dries almost instantly. Therefore, this saves time during production.

Eco-Friendly Options Exist

Some UV coatings use materials that are safer for the environment, making it a greener choice.

Disadvantages of UV Coating

Hard to Write On

The smooth, shiny surface does not work well with pens or pencils. Writing on UV-coated paper can be very difficult.

Costs More

Adding UV coating can increase printing costs. If you are on a tight budget, it might not be the best option.

Not Suitable for All Paper Types

Thin paper may bend or curl when coated with UV. However, it works best with thicker paper or cardstock.

Not biodegradable

while there are eco-friendly options, many UV coatings are not biodegradable, which can affect the environment.

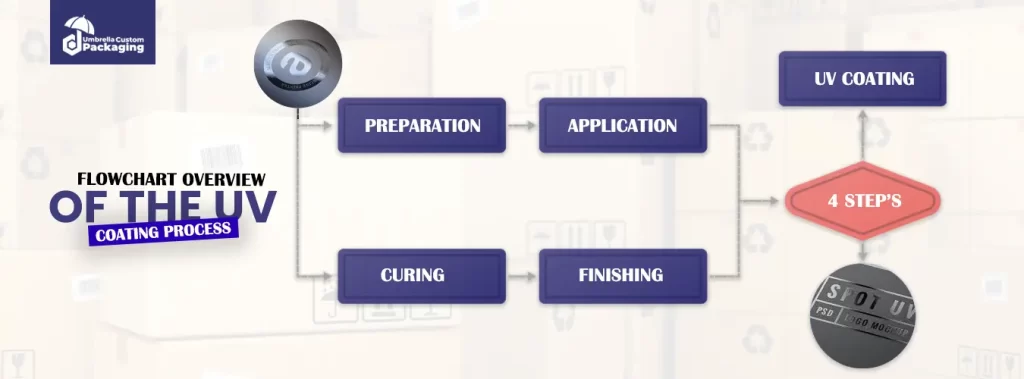

Flowchart Overview of the UV Coating Process

Here is a simple systematic guide to the UV coating process:

Preparation

- Clean the surface to remove dust or dirt.

- Adjust the equipment to ensure smooth operation.

- Choose the type of coating (e.g., glossy, matte, or spot UV).

Application

- Apply the liquid coating evenly on the surface.

- Monitor the thickness to ensure consistency.

- Decide between covering the entire surface or specific areas (spot coverage).

Curing

- Expose the coated surface to ultraviolet (UV) light.

- Control the light’s intensity for proper drying.

- Manage cooling to prevent overheating.

Finishing

- Inspect the coated product for quality.

- Add additional textures or effects if required.

- Send the finished item to the next stage of production.

However, this flow ensures a smooth and high-quality UV coating process!

Applications of UV Coating:

UV coating is used in many cool ways. Here are some examples:

- Brands use UV coating to create vibrant, high-gloss finishes on lipstick boxes, skincare packaging, and perfume cartons.

- In addition, companies apply UV coating on product labels, folding cartons, and bottle packaging.

- As a result, a shiny or matte finish makes your business card look professional and attractive.

- Moreover, high gloss UV coating is widely used for book covers, catalogs, paper bags, paper hang tags, and brochures while spot UV is applied to emphasize logos or product images on covers.

- Furthermore, brands use this coating on corrugated boxes, mailing cartons, and box inserts to protect products during transit and keep them looking professional upon arrival.

- UV coating adds a special touch to greeting cards, making them shine and stand out for occasions like birthdays, weddings, and holidays.

Get Expert Advice on UV Printing and Packaging Solutions

UV coating is a fantastic way to make your printed materials look amazing and last longer. Whether you want shiny posters, classy business cards, or creative packaging, it can do it all. It is like adding a touch of magic to your designs.

If you have any questions about UV printing or other printing methods, we are here to help at Umbrella Custom Packaging. Printing can sometimes feel overwhelming because there are so many options, like UV coating, embossing, and foil stamping. Fortunately, our team is always ready to explain these techniques in simple terms so you can choose the perfect option for your project.

At Umbrella Custom Packaging, we believe that every detail matters. Whether you need shiny finishes for packaging, creative textures for business cards, or durable prints for promotional items, we can guide you through the process. Moreover, with our experience, we can recommend the best printing solutions that fit your needs, budget, and design goals.

Therefore, do not hesitate to contact us! We are happy to answer your questions, discuss your ideas, and help bring your vision to life. However, from the first step to the finished product, we will make sure you are thrilled with the results. Let us help make your packaging and printing stand out!

Table of Contents

Latest Articles

© 2025 Umbrella Packaging All rights reserved.