How Do Manufacturers Make Cardboard Boxes?

A cardboard box is something we use all the time. You have probably seen them when getting deliveries, packing for a trip, or even organizing your toys.

However, these boxes are containers made from a type of material called corrugated cardboard. This material consists of layers of paperboard or Kraft paper, often with one or more wavier (corrugated) layers in between for added strength.

We commonly use these boxes for shipping, storing, and packaging goods, offering a lightweight yet durable option for protecting products during transport. Moreover, they are available in various sizes and types, such as single, double, or triple-wall boxes, which offer different levels of protection depending on the number of layers of material used.

It All Starts With Trees and Paper

First, let us talk about where cardboard comes from. The process starts with trees. Trees have fibers called cellulose that are perfect for making paper. Factories also use recycled paper from old boxes, newspapers, or packaging. The trees or recycled paper are turned into a wet, mushy material called pulp. This pulp is the base for making paper.

Turning Pulp into Paper

Next, the manufacturers spread out the pulp into thin sheets to make paper. Giant machines roll and dry the sheets until they become strong and smooth. These paper rolls are sometimes thin, like what you use in school, but for cardboard, the paper needs to be thicker and sturdier.

Creating Corrugated Cardboard

These boxes are not just made of one layer of paper. We make them from three layers:

- A flat top layer.

- A wavy middle layer (corrugation)

- A flat bottom layer.

The wavy layer is what makes cardboard strong but light. To create it, factories use machines called corrugators. These machines heat and press the paper to give it its wavy shape. Then, we use glue to sandwich the wavy layer between the two flat layers.

Once you glue these three layers together, they create corrugated cardboard.

Cutting and Shaping the Cardboard

Now that the cardboard is ready, it’s time to turn it into box shapes. Then, send large sheets through machines that cut them into specific sizes.

Adding Designs

Before folding the box, some companies enhance its appearance. They print logos, brand names, or colorful pictures directly onto the cardboard. As a result, the packaging becomes more attractive and visually appealing. For example, a box for a toy company might have bright, fun images printed on it to attract kids.

Folding and Gluing

Now comes the magic moment! First, machines fold the cardboard along the scored lines, turning the flat pieces into actual box shapes. Next, workers glue or tape the edges together.

Some boos are left flat at this stage so they can be stored or shipped easily. They will fold the boxes into shape only when they are ready to use them.

Shipping the Finished Boxes

Once workers make the boxes, they pack and send them to stores, factories, or homes. We use these boxes to carry everything from books to snacks to electronics. In addition, they protect the items inside and make transportation much easier.

Recycling: The Box’s Second Life

Here’s something cool: these boxes can be recycled! After a box has been used, you can put it in the recycling bin instead of throwing it away.

Here’s how recycling works:

1. Take the box to a recycling center.

2. Next, it’s shredded into tiny pieces and turned back into pulp.

3. Then, use the pulp to create new paper or cardboard.

In the end, this process saves trees, reduces waste, and helps protect the planet.

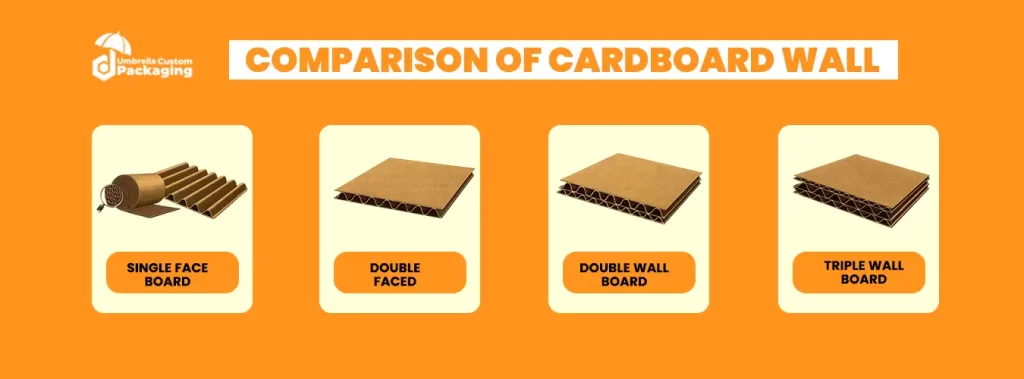

Comparison of Cardboard Wall:

| Type of Wall |

Structure |

Strength |

Weight |

Common Uses |

| Single Face Board |

1 flat layer + 1 wavy layer |

Low to Medium |

Light-weight |

Lining inside boxes, protective wrapping for fragile items. |

| Single Wall Board |

2 flat layers + 1 wavy layer |

Medium |

Light to medium |

Shipping, storage, retail packaging. |

| Double Wall Board |

2 flat layers + 2 wavy layers |

High |

Medium |

Electronics, appliances, long-distance shipping. |

| Triple Wall Board |

3 flat layers + 3 wavy layers |

Very High |

Heavy |

Industrial machinery, bulk goods, heavy-duty packaging. |

Why Are Cardboard Boxes So Special?

These boxes are amazing because:

First, they are lightweight yet strong, making them easy to carry and reliable.

Additionally, they can be recycled, which is great for the environment. Moreover, cardboard boxes are versatile you can use them for packing, storing, creating, and even playing!

Choosing the Right Cardboard Box

The type of box you choose depends on what you need. These boxes come in various types, each designed to meet different packaging, storage, and transportation needs. For example, Umbrella Custom Packaging offers a wide variety of customizable boxes for different uses, including custom Kraft corrugated boxes, presentation boxes, and cosmetic boxes. Here are the most common types of these boxes:

Die-cut boxes are customized into unique shapes and sizes using die-cut machines. They are often used for retail packaging, product displays, and promotional purposes, such as shoe boxes, gift boxes, and custom packaging.

Similarly,corrugated trays are open boxes with low walls, used for displaying products or storing lightweight items such as fruit trays, bakery trays, and beverage holders.

In contrast,telescopic boxes consist of a base and a lid that fits over it, allowing the lid to slide to adjust the height. Moreover, we often use them for packing long or irregularly shaped items, like picture frames, fishing rods, and telescopes.

Furthermore,archive boxes are sturdy boxes with lids designed for storing documents and files, often with handles for easy carrying, and used for office or home organization, such as filing boxes for papers, photos, or magazines.

On the other hand,folding cartons are lightweight boxes made from a single sheet of cardboard that folds into shape, commonly used for retail packaging, such as cereal boxes, gift boxes, and cosmetic packaging.

Finally, postal boxes are small, lightweight boxes designed for mailing items safely, perfect for shipping small or medium-sized goods like subscription boxes, e-commerce packaging, and small parcels.

All In All

In conclusion, cardboardboxesare made from layers of paper and a wavy layer in the middle to give them strength and lightness. The process starts with pulp, made from trees or recycled paper, which is turned into sheets and formed into corrugated cardboard. This is then cut, printed, and folded into different shapes and sizes for packing and shipping.

There are various types of boxes, such as single-wall, double-wall, and heavy-duty boxes, each suited for different uses. These boxes are not only useful and versatile but also recyclable, making them an eco-friendly option for packaging.

Where you can get the Best!

Umbrella Custom Packaginghas a lot of experience in making strong, eco-friendly, and biodegradable cardboard boxes. They specialize in creating boxes that are both durable and good for the environment, using sustainable materials. We design these boxes to safely pack and ship products while reducing waste. With a focus on quality and environmental responsibility, they offer packaging solutions that meet the needs of businesses looking for reliable and green options.

Table of Contents

Latest Articles

© 2025 Umbrella Packaging All rights reserved.