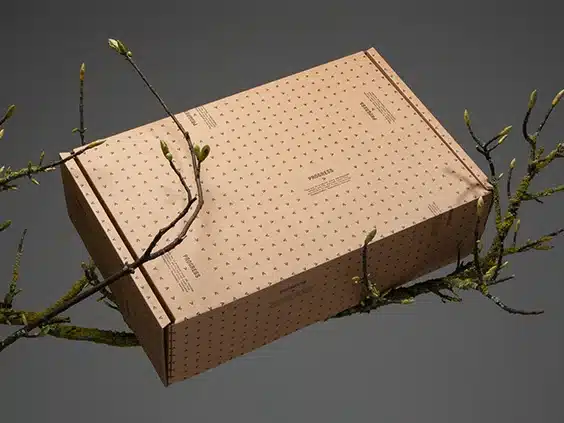

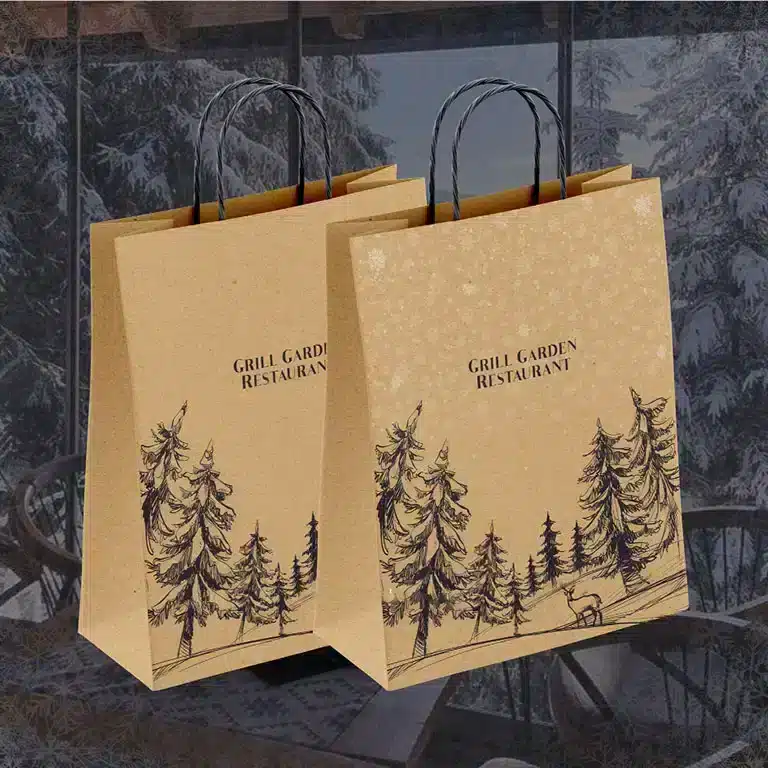

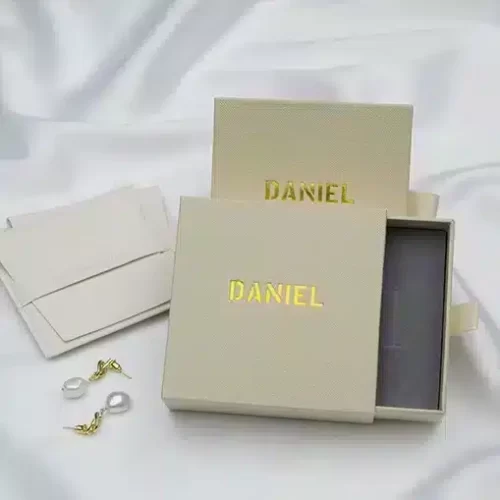

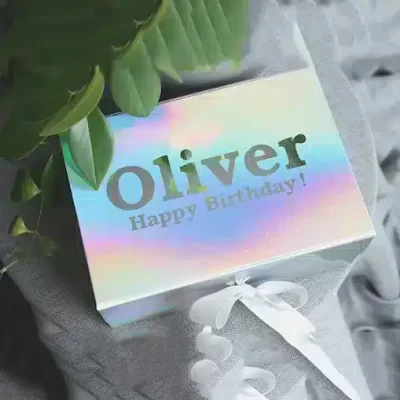

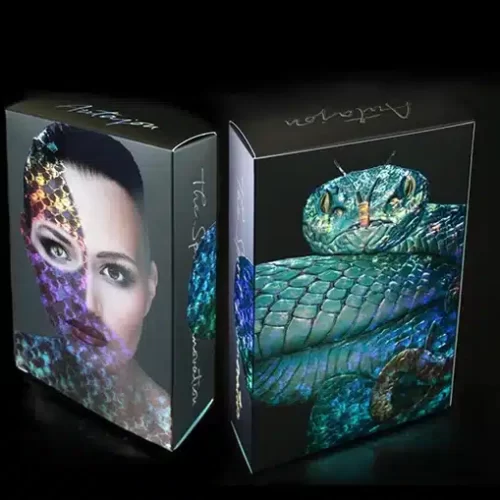

Discover Our Custom Packaging Variety

Check out all the different types of boxes we have at Umbrella Custom Packaging! We have special categories for boxes that you can customize just the way you like. Choose the size, the material, or how it looks. So, have a look and pick the perfect box for you!

Custom Box Material Guide: Finding the Perfect Fit

Let's explore the Types of Materials for Your Unique Packaging.

Get Price Quote

Enhance Your Product Presentation with Our Special Packaging Features

Your Packaging Partner: What Sets Umbrella Custom Packaging Apart

Need Box Template to design?

Get a quick template file from us, where you can put your design and save some good time. You can also send us the artwork to input in a template and send it your way for your vision.

Making boxes just the right size, building creative structure, or enhance functionality is simple. Just Provide Following Information.

- Select/provide the Box style

- Provide the Box Dimensions/Size

- Share your additional thoughts

Umbrella Custom Packaging has Production Units Across the Globe

Umbrella Custom Packaging tend to rely on its in-house production units most of the time in order to expedite the orders for the customers.

Umbrella Custom Packaging have its various printing facilities outside USA where the orders are being produced at the lowest possible cost with same turnaround time.

Umbrella Custom Packaging make your order even more cost effective by providing you the free ground and air freight and delivers the orders on time.

Simple Steps to get the Custom Packaging Produced

Following are few steps which provide the complete Guide.

Submit a request for free custom quote first through our website or calling our customer service representative. You will have the prices in 30 minutes.

Match the price with your budget line and ask the representative to beat that. We will try our best to give you the lowest possible prices here at Umbrella Custom Packaging.

Give your approval on the prices to proceed with the order right away. We will be delighted to take you on board with Umbrella Custom Packaging throughout your packaging needs.

Share your artwork file to the dedicated representative so that our design department can create a 3D digital mockup for you. You can ask for the template to design it by your own as well.

It’s a very important step. Our Creative design team can provide you some creative design suggestions if you ask for that. It’s a certain value addition to your packaging.

After you receive a 3D digital Mockup for your packaging, you need to approve that in order to proceed ahead. You can ask for frequent changes until it satisfies you before you approve it.

The next step is to make the payment and our payment methods are very secure. the first one is that you can make it through your debit/card.

The other method is for the PayPal users. We accept the payments through PayPal as well. Refund Policy is mentioned on our website.

For the bigger amounts we suggest Wire/ACH bank transfers in order to avoid the payment processor’s taxes.

A final specification sheet will be sent to you before we send your order towards to the production after the payment.

The sample run will be sent to the customer before the bulk order if it’s required or if the customer go for it.

The order will be produced in the given time span and will be sent toward the Quality Control unit before shipping.

Our QC department will check the order and approve it after certain text if it comes good. After It will be sent to the shipping department.

The Order will be shipped right away after it is cleared from the QC department. Tracking ID will be provided and the order will be delivered.

The customer’s thoughts and suggestions on the order will be taken and displayed on our media. Also, the issue will be addressed.

One of our customer service representative will be appointed to the customer whoever places the order with us. He/she will keep the customer in a loop so to make the next order placement super easy for both the customer and company.

The customer will be regularly informed about the discounts that the company offers every month and year like month-end and Christmas discounts.

Umbrella Custom Packaging will ultimately build this route to a successful and profitable business relationship with the customer.

We Fulfil the standards of the Packaging Industry.

Umbrella Custom Packaging follows strict standards, much like a recipe, ensuring each box is the right size, crafted from top-quality materials, and designed to perfection. With attention to detail and quality control, they deliver custom boxes that are both reliable and customized to your preferences.

Customer Reviews

Share your true experience with us by writing a review below

What Is Custom Packaging?

A Complete Guide