Choosing between Digital and Offset Printing for Packaging: Which is Right for You?

When choosing between digital and offset printing for packaging, consider factors such as the number of packages, cost, and the need for custom designs. For large orders, offset printing is the better option as it becomes more cost-effective with higher quantities while maintaining excellent quality.

On the other hand, if you need quick printing, fewer packages, or special designs, digital printing might be a better choice. In addition, digital printing is faster, allows for custom prints, and is great for smaller orders. Ultimately, the right choice depends on your packaging needs and budget.

What is Offset Printing?

Offset printing is a traditional method where the image is first transferred to a plate and then onto the printing surface, like paper. In particular, this method works best for large print jobs because it becomes cheaper per copy as the quantity increases. For example, it's perfect for printing thousands of copies of things like books, brochures, and newspapers.

However, it takes more time to set up, so it may not be cost-effective for small runs. On the plus side, the print quality is very sharp and consistent, which makes it ideal for detailed designs and color-rich images.

How Offset Printing Works?

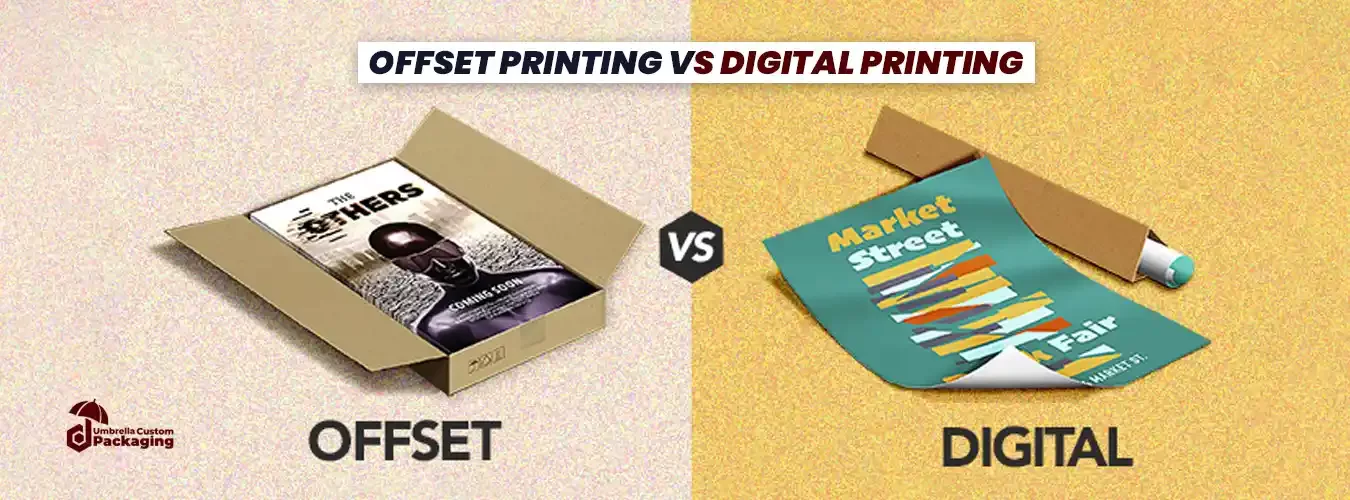

Offset printing is a process where the image or text is first transferred from a metal plate to a rubber blanket, and then onto the printing surface, such as paper. First, the process begins with preparing the printing plate. We create a plate for each color in the design, and these plates carry the design to be printed.

- Next, we apply ink to the plate, but it only sticks to the areas where the design is present. This happens because of a chemical process that keeps the non-design areas ink-free

- After that, the plate transfers the inked design to a rubber blanket. This step is essential because it protects the printing surface and ensures even ink distribution.

- Then, the rubber blanket transfers the inked design onto the paper or other printing material, resulting in the final printed image.

- Finally, the printed material goes through a drying process to set the ink before any additional steps, like cutting or binding.

What is Digital Printing?

Digital printing eliminates the need for plates and prints images directly onto the material. This approach speeds up the process and reduces costs for smaller quantities because it avoids setup expenses. Additionally, it works well for customized prints, such as personalized invitations or variable data printing, where each piece contains unique information.

Although the print quality is generally good, it may not be as sharp as offset printing for larger jobs. Ultimately, digital printing is perfect for short runs and quick turnarounds, but the cost per piece remains the same no matter how many you print.

How Digital Printing Works?

Digital printing is a modern method that directly transfers an image or design from a digital file to the printing surface without using plates. The process starts with creating or uploading a digital design file, such as a PDF or image file, to the printer’s software.

- Next, the printer processes the file and prepares the design for printing. Unlike offset printing, this step does not require plates, which saves time and setup costs.

- After that, the printer applies the ink or toner directly to the material, such as paper, fabric, or plastic. This is done using advanced technologies like laser printing or inkjet printing.

- Then, the ink or toner is then quickly dried or cured, ensuring the design stays sharp and vibrant.

- Finally, the printed material is ready for any finishing touches, such as cutting, folding, or laminating, depending on the project.

Comparison between Offset Printing and Digital Printing

| Feature |

Offset Printing |

Digital Printing |

| Printing Process |

First, plates are created, and ink is transferred to the surface via rollers |

In contrast, images are directly printed onto the surface without the need for plates. |

| Cost Efficiency |

Initially, setup costs are higher, but it becomes cost-effective for large quantities. |

On the other hand, it is economical for smaller quantities because there are no setup costs. |

| Print Quality |

It offers consistent and high-quality prints, especially for detailed images. |

However, digital printing delivers good quality but may not match the sharpness of offset prints. |

| Turnaround Time |

Since setup takes time, it is slower for short runs. |

Conversely, it is faster as no setup is required. |

| Volume Suitability |

Best suited for high-volume printing. |

By comparison, it is ideal for low to medium-volume printing |

| Customization |

Customization is limited because it uses pre-made plates. |

Meanwhile, digital printing excels at customization, such as variable data printing. |

| Material Options |

It supports a wide variety of materials, including textured papers. |

Although digital printing works with fewer materials, advancements are expanding its capabilities. |

Advantages of Offset Printing:

- Firstly, offset printing offers high-quality prints with sharp, clear images and smooth colors, making it perfect for detailed designs.

- In addition, it becomes more cost-effective as the print quantity increases, which makes it ideal for large print runs.

- Moreover, offset printing ensures consistent results, so the quality remains the same from the first to the last print.

- Another advantage is its versatility, as it can print on a wide variety of materials, including textured paper and cardboard.

- Finally, once the setup is complete, the printing process is fast, which helps in completing large orders efficiently.

Advantages of Digital Printing:

- Firstly, digital printing offers a quick setup, making it ideal for smaller print runs and fast turnaround times.

- In addition, it allows for high levels of customization, such as personalized prints or variable data, without additional cost.

- Moreover, there is no need for printing plates, which reduces the setup time and overall cost for small orders.

- Another advantage is its ability to print on a wide variety of materials, including paper, fabric, and even plastic.

- Finally, digital printing ensures that each print is as good as the first, providing consistent quality throughout the run.

Offset vs. Digital Printing: Which is best for Your Project?

Both offset and digital printing have their strengths, and the best choice depends on your specific needs. If you need large quantities, offset printing is more cost-effective and delivers consistent, high-quality results. On the other hand, digital printing is faster and better for small runs or personalized designs. In the end, it’s all about balancing cost, speed, and customization to find the printing method that works best for your project.

Umbrella Custom Packaging specializes in both offset and digital printing. We provide high-quality solutions for all types of packaging needs. For large orders, we use offset printing, ensuring consistent quality and cost-effectiveness. On the other hand, our digital printing is ideal for smaller runs and personalized designs.

Moreover, whether you need sharp, detailed prints for bulk orders or fast, customized packaging, we apply our expertise and technology to deliver excellent results. Ultimately, we ensure every project meets your specific needs with precision and care.

Table of Contents

Latest Articles

© 2025 Umbrella Packaging All rights reserved.