Understanding the Aqueous Coating

Aqueous coating is a special water-based liquid that people use to protect and shine paper products like brochures, business cards, and book covers. First, workers print the design on the paper, and then they apply the coating to make it look glossy or matte.

Because it is water-based, it dries quickly and doesn’t smell bad like some other coatings. Moreover, it’s eco-friendly, which means it’s safer for the environment. Another great thing about aqueous coating is that it makes paper stronger and more resistant to scratches, dirt, and fingerprints. For example, if you spill a little water on a coated business card, the ink won’t smudge as easily.

Many companies use this coating because it’s affordable, dries fast, and keeps printed materials looking fresh for a long time. So next time you see a shiny flyer or a smooth magazine cover, it probably has aqueous coating on it!

Aqueous Coating in Packaging

Aqueous coating is a thin, water-based layer that companies add to packaging to make it look better and last longer. First, they print the design on the box or wrapper, and then they spray or roll on the coating to give it a shiny or smooth finish. Since it’s made with water, it dries fast and doesn’t harm the environment like some chemical coatings.

Moreover, it helps protect the packaging from scratches, moisture, and fingerprints, keeping it fresh and clean. Many food and product brands use aqueous coating because it’s safe, affordable, and makes their packaging stand out.

For example, a cereal box with this coating will stay bright and colorful even if it gets bumped on store shelves. It also makes labels and logos look more professional. So next time you see a shiny snack bag or a smooth medicine box, it probably has an aqueous coating to keep it looking great!

It works like magic in 4 ways:

1) It keeps fingerprints and little scratches away

2) It makes colors look brighter (or softer if you want)

3) It dries in just minutes, so we can make things faster

4) It’s made mostly from water, so it’s safer for our planet

Aqueous Coating Process

Surface Preparation: First, cleaning and prepping the printed material for coating

Coating Application: Next, roll or spray on the water-based coating

Drying Process: Then, warm air dries it in minutes

Quality Inspection: After that, check the uniform coating and make sure of a smooth finish

Final Processing: Finally, cut, fold, and package the product

This streamlined process ensures a protective, high-quality, and eco-friendly finish for printed surfaces.

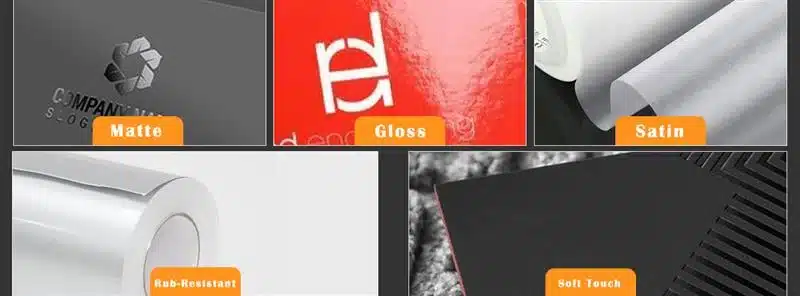

Types of Aqueous Coatings Used in Packaging

Aqueous coatings come in different finishes, each with its special look and purpose.

Gloss Coating

This type makes packaging shiny and bright, helping colors pop. It also adds a smooth, slippery feel. Many candy wrappers and shiny product boxes use gloss coating.

Matte Coating

Unlike gloss, matte gives a dull, non-reflective finish that looks elegant and professional. Books, luxury product packaging, and business cards often use matte coating.

Satin Coating

This is a mix between gloss and matt, it has a slight shine but isn’t too flashy. It’s great for brochures and product labels that need a balanced look.

Soft-Touch Coating

This special coating feels velvety and smooth, almost like suede. High-end cosmetics and tech packaging often use it to make products feel more luxurious.

Rub-Resistant Coating

It protects prints from scratches & smudges. Keeps packaging looking fresh through handling and shipping.

Each type protects the print while giving a unique look and feel, so companies choose based on their packaging needs!

Benefits Of Aqueous Coating In Packaging

Here are the key benefits of aqueous coating in packaging:

Durability: protects packaging from smudging, scratches, and moisture damage, keeping it in excellent condition.

Quick Drying: Speeds up production time, making the printing process more efficient.

Enhanced Appearance: Available in various finishes like glossy, matte, satin, and soft-touch, helping brands achieve their desired look.

Eco-Friendly: Water-based and contains fewer harmful chemicals, making it a sustainable choice for businesses.

Improved Color & Readability: Glossy coatings make colors vibrant, while matte coatings reduce glare for easier reading.

Premium Feel: adds a smooth or textured surface, making packaging feel high-end and professional.

Comparing Aqueous Coating and Spot UV Finishes

When selecting a protective finish for your printed materials, aqueous coating and spot UV serve different purposes. Here’s a comparison to help you choose:

Aqueous Coating

- Applies an even, water-based layer across the entire surface

- Available in multiple finishes: glossy, matte, satin, and soft-touch

- Quick-drying and environmentally friendly

- Provides general protection against wear and moisture

- Cost-effective solution for large print runs

- Ideal for: product packaging, brochures, business cards

Spot UV

- Uses ultraviolet light to cure a glossy coating on specific design elements

- Creates noticeable contrast between coated and uncoated areas

- More expensive due to a specialized application process

- Adds texture and dimension to selected areas

- Best for emphasizing logos, text, or decorative elements

- Commonly used for: premium packaging, book covers, high-end marketing materials

Making Your Decision

Consider aqueous coating when you need:

- Full coverage protection

- A budget-friendly option

- Fast production times

Opt for spot UV when you want:

- Selective glossy accents

- A luxury appearance

- Tactile design elements

For maximum visual impact, some projects combine both techniques using aqueous coating for overall protection while adding spot UV highlights to key design features. Your choice ultimately depends on your project’s requirements, desired aesthetic, and budget.

How Different Industries Use Aqueous Coating

Aqueous coating is like an invisible shield that makes printed things look better and last longer. Here’s how different jobs and businesses use it:

1. Food Packaging

Keeps cereal boxes, snack bags, and frozen food boxes shiny and colorful

Protects from fingerprints and small spills so the pictures stay bright

2. Medicine & Vitamins

Makes medicine bottles and vitamin labels smudge-proof

Helps important instructions stay clear and easy to read

3. Books & Magazines

Gives book covers a smooth feel (soft touch) or pretty shine (gloss)

Stops magazines from getting dirty when people flip through them

4. Shopping & Products

Makes shoe boxes, toy packages, and makeup boxes look fancy

Prevents scratches when products sit on store shelves

5. Office Supplies

Helps business cards feel extra nice (matte or silky)

Keeps flyers and brochures from fading in sunlight

Get Expert Advice on Aqueous Printing and Packaging Solutions

Aqueous coating is a fantastic way to make your printed materials look amazing and last longer. Whether you want shiny posters, classy business cards, or creative packaging, it can do it all. It is like adding a touch of magic to your designs.

If you have any questions about this printing or other printing methods, we are here to help at Umbrella Custom Packaging. Printing can sometimes feel overwhelming because there are so many options, like UV coating, aqueous coating, embossing, and foil stamping. Fortunately, our team is always ready to explain these techniques in simple terms so you can choose the perfect option for your project.

At Umbrella Custom Packaging, we believe that every detail matters. Whether you need shiny finishes for packaging, creative textures for business cards, or durable prints for promotional items, we can guide you through the process. Moreover, with our experience, we can recommend the best printing solutions that fit your needs, budget, and design goals.

Therefore, do not hesitate to contact us! We are happy to answer your questions, discuss your ideas, and help bring your vision to life. However, from the first step to the finished product, we will make sure you are thrilled with the results. Let us help make your packaging and printing stand out!