Corrugated packaging is a type of box or container made from special cardboard. This cardboard is unique because it has three layers: an inside liner, an outside liner, and a wavy layer in the middle called fluting. Because of this, the fluting makes the packaging strong and lightweight at the same time.

For this reason, people use corrugated boxes to ship things safely, such as toys, food, and electronics. In addition, these boxes are good for the environment because they can be recycled and reused. As a result, they help reduce waste.

History of Corrugated Packaging:

The history of corrugated packaging is interesting! To begin with, in 1856, two people in England invented corrugated paper, but at first, it was only used for stiffening hats. A few years later, in 1871, an American named Albert Jones started using corrugated paper to protect fragile items like glass during shipping.

After that, other people began adding flat layers to both sides of the wavy paper, creating the corrugated cardboard we know today. Over time, businesses realized it was a great way to ship goods. Because of this, it quickly became very popular. Today, almost everything we buy online or in stores has traveled in a corrugated box!

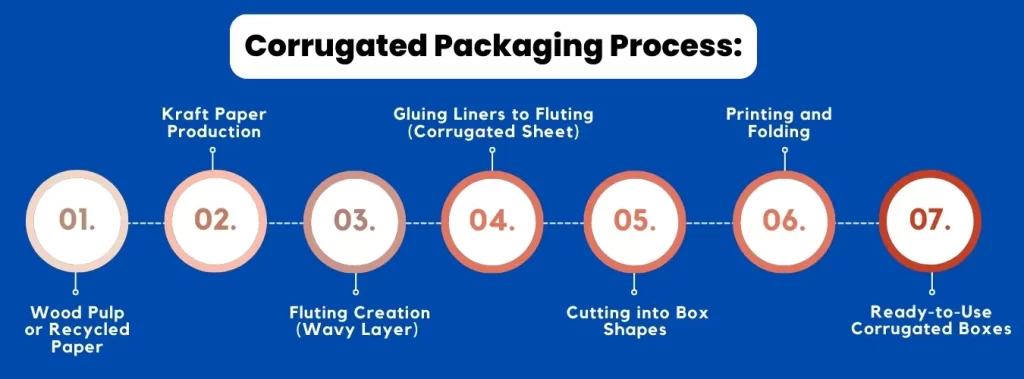

Process of Corrugated Packaging:

Here’s an explanation of the process of making corrugated packaging

Making the Paper

First, Kraft paper is made from wood pulp or recycled paper. The paper is processed and dried into large rolls, which are strong and durable.

Creating the Corrugated Sheet

Next, Kraft paper goes through heated rollers that create the wavy fluting. At the same time, flat Kraft paper liners were glued to both sides of the fluting. This forms a sandwich-like structure, creating strong corrugated cardboard.

Cutting and shaping

After that, large machines cut the cardboard into specific sizes and shapes. The machines also make folds, flaps, and creases based on the box design.

Printing and finishing

Finally, printers add designs or logos to the boxes. Workers fold, glue, or staple them and pack them flat. This process prepares the boxes for shipping to customers.

Flow Sheet for Corrugated Packaging Process:

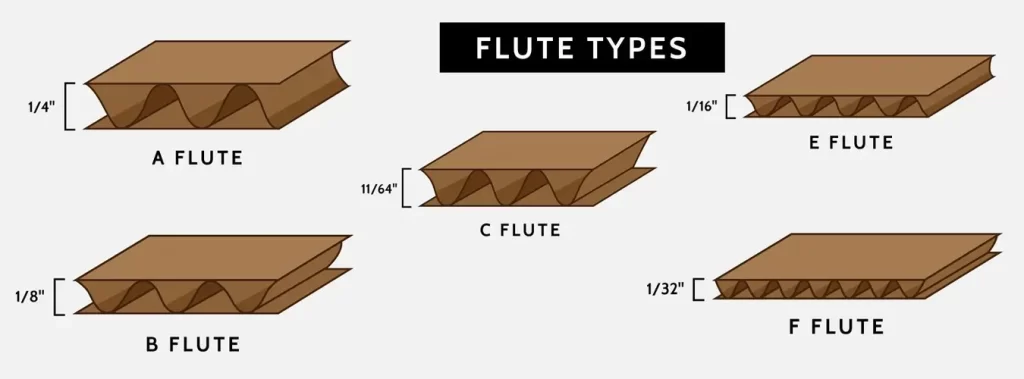

Corrugated Flute Types (Flute Grades)

Corrugated packaging groups by the type of flute, which is the wavy layer between the flat liners. Simply put, the size and thickness of the flute affect how strong, soft, or flexible the box is. Here are the main types of flutes explained simply:

1. A-Flute

To start, A-Flute is the thickest kind, with about 36 waves (flutes) per foot. Because it’s so thick, it gives great cushioning and strength. This makes it good for packing fragile and heavy items like glass or electronics.

2. B-Flute

Next, the B-flute is thinner than the A-flute, with about 49 flutes per foot. Because it’s thinner, it’s tougher against punctures and works well for smaller, stronger items like canned goods or drinks. Moreover, we often use it for display boxes.

3. C-Flute

After that, C-Flute is the most common type, with about 41 flutes per foot. It’s a balance between cushioning and strength. For example, we use it in shipping boxes, food packaging, and general cartons.

4. E-Flute

In addition, the E-Flute is thinner, with about 90 flutes per foot. Because it’s so light, it’s perfect for packaging that needs printing, like pizza boxes and retail packaging.

5. F-Flute

Lastly, the F-Flute is the thinnest, with about 125 flutes per foot. Since it’s so thin, we use it for small, fancy packaging, like jewelry, cosmetics, and gift boxes.

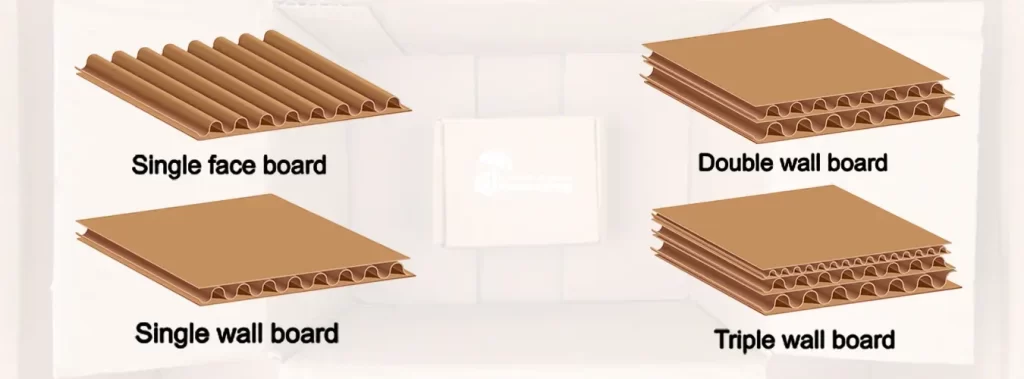

Types of Corrugated Board:

There are different types of corrugated packaging, each designed for specific uses. Let’s explore them step by step:

Single Face Board

First, this type has one layer of fluting attached to one flat liner. It is flexible and wraps around fragile items like glass or ceramics for protection. However, it is not strong but we use it for cushioning.

Single Wall Board

Next, this common type has one layer of fluting between two flat liners. It is lightweight and strong, making it ideal for packaging books, food, and toys.

Double Wall Board

After that, double wall boards have two layers of fluting and three flat liners. They are much stronger and handle heavy items like furniture and appliances.

Triple Wall Board

Finally, triple wall boards are the strongest type, with three layers of fluting and four liners. They are perfect for extremely heavy items like industrial equipment or large machines.

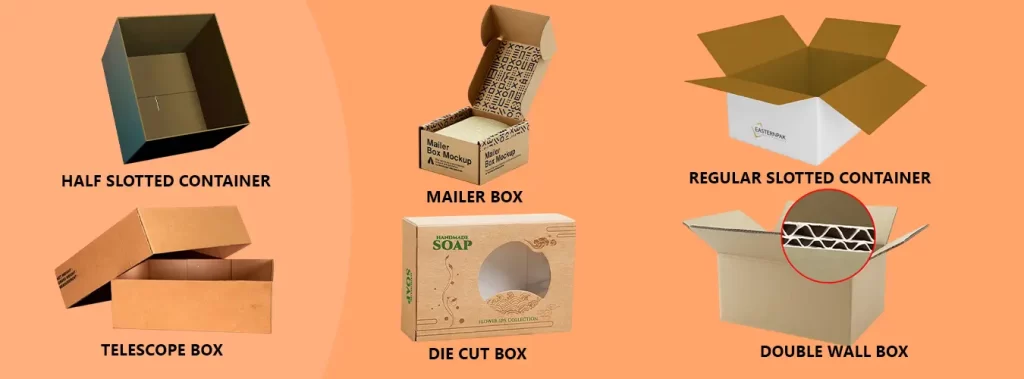

Popular Corrugated Box Styles:

Corrugated boxes come in many styles, each designed for different uses. Let’s look at some of the most popular ones step by step:

Regular Slotted Container (RSC

To begin with, this is the most common box style. It has flaps on the top and bottom that meet in the middle when closed. Because it’s simple and strong, it’s great for shipping almost anything, like books, toys, and food.

Half-Slotted Container (HSC)

Next, this box is similar to the RSC, but it only has flaps on one side (the bottom). For this reason, it’s useful for storing or displaying items that need to stay open on the top.

Full Overlap Box (FOL)

After that, in this style, the flaps on the top and bottom fully overlap each other when closed. As a result, it gives extra strength, making it good for heavy or fragile items like machinery or glass.

Die-Cut Box

In addition, these boxes are custom-made with special shapes or cutouts. For example, they are great for retail displays or packaging products like electronics or cosmetics. Moreover, they look neat and professional.

Telescope Box

Another popular option is the telescope box. This box has two parts: a top and a bottom. The top (lid) fits over the bottom, like a telescope. Because of this, it’s good for packaging flat items like picture frames or books.

Mailer Box

Furthermore, this stylish box folds together and locks without needing tape. It’s especially perfect for e-commerce packaging, like sending clothes, gifts, or subscription boxes.

Double-Wall Box

Finally, this is a stronger box with two layers of corrugated material. As a result, we often use it for heavy-duty shipping or packing bulky items like appliances or tools.

Key Benefits of Corrugated Packaging

Corrugated packaging has many benefits that make it a popular choice for shipping and storing items. Let’s explore these advantages step by step:

Strong and Durable

First, corrugated boxes are strong and can handle heavy items. Because of their design, they protect products from damage during shipping or storage. For example, they can safely carry things like books, electronics, or even furniture.

Lightweight

Next, even though they are strong, corrugated boxes are lightweight. This makes it easier to carry or move them. In addition, the lightweight helps reduce shipping costs.

Affordable

Another great benefit is that corrugated packaging is affordable. Because manufacturers make it from recyclable materials like paper, they can produce it at a lower cost. As a result, businesses can save money while still protecting their products.

Eco-Friendly

In addition, corrugated packaging is good for the environment. Since it’s recyclable and reusable, it helps reduce waste. For this reason, it’s a sustainable choice for businesses and consumers.

Customizable

Furthermore, manufacturers easily customize corrugated boxes. They create them in different sizes, shapes, and designs to fit specific products. Companies also print logos or branding on the boxes, which makes them great for marketing.

Good Protection

Finally, the wavy layer (fluting) in corrugated packaging provides extra cushioning. Because of this, it absorbs shocks and protects fragile items like glass or ceramics.

Corrugated Packaging vs. Cardboard Boxes

Corrugated boxes and cardboard boxes may seem similar, but they have key differences.

First, corrugated boxes have three layers: two flat liners and a wavy fluting layer in the middle. This structure makes corrugated boxes stronger and more durable for protecting items during shipping. The fluting adds strength, making these boxes ideal for heavier or fragile goods. For instance, businesses use corrugated boxes to ship electronics, furniture, and other bulky items.

On the other hand, manufacturers use a single layer of thick paperboard to make cardboard boxes. They are lighter and cheaper but provide less protection than corrugated boxes. Cardboard boxes work well for lighter items like food, cosmetics, or retail products. In summary, corrugated boxes are stronger and better for shipping, while cardboard boxes suit lightweight, less fragile goods.

Uses of Corrugated Packaging in Various Industries

Here are the main uses of corrugated packaging:

Shipping Goods:

Protects items during transport (e.g., electronics, clothes).

Storing Items:

Keeps products safe and organized in warehouses.

Retail Packaging:

Used for packaging and displaying products in stores (e.g., shoes, food).

Food Packaging:

Keeps food fresh during shipping (e.g., fruits, and vegetables).

Display Boxes:

Attracts customers with custom designs for in-store displays.

The Future of Corrugated Packaging

The future of corrugated packaging looks bright and exciting! To begin with, companies are focusing more on making corrugated packaging even more eco-friendly. In addition, advancements in technology are making it easier to design and produce custom shapes and sizes for different products. As a result, businesses can now create packaging that fits products perfectly, reducing waste.

Moreover, the rise of e-commerce is increasing the demand for corrugated packaging since more people shop online. In conclusion, as businesses continue to focus on sustainability and innovation, the future of corrugated packaging will be stronger, smarter, and better for the planet.

Your Trusted Source for High-Quality Corrugated Packaging

If you are looking for the best-corrugated packaging, Umbrella Custom Packaging is a perfect choice. We specialize in creating high-quality corrugated boxes that meet all your needs. Whether you need durable boxes for shipping, custom designs for branding, or eco-friendly options, we have you covered. Our team uses top-notch materials and advanced technology to make sure every box we create is strong, reliable, and tailored to your needs.

In addition, we pride ourselves on offering excellent customer service. From start to finish, we work closely with you to design and deliver the perfect packaging solution. No matter the size or quantity, we ensure fast production and on-time delivery. By choosing our company, you can trust that your products will be packed with care and arrive safely every time.