Measuring a box may seem simple at first, but when it comes to custom packaging, you obviously need to focus on accuracy. To get the best results, you must pay attention to every single detail. While the process is not complicated, taking the time to measure correctly ensures your packaging fits perfectly and protects your product effectively.

Furthermore, box dimensions influence every aspect of packaging. For example, they determine the type and amount of materials you will use. In addition to that, they also directly affect production costs, shipping fees, and even storage expenses. Therefore, you need to get these measurements right to avoid unnecessary issues.

On top of that, reducing empty space inside the box has several benefits. First, it minimizes the chances of your product moving around, which significantly reduces the risk of damage. Secondly, it helps you save money by lowering your material and shipping costs. For these reasons, accurate measurements are not just important, they are essential.

To make things even easier for you, we have created a systematic guide. This guide will show you how to measure a box correctly, how to calculate its volume, and, most importantly, how to avoid common mistakes that could affect your measurements. By following these steps, you can ensure that your packaging is both cost-efficient and effective!

The Dimensions of a Box:

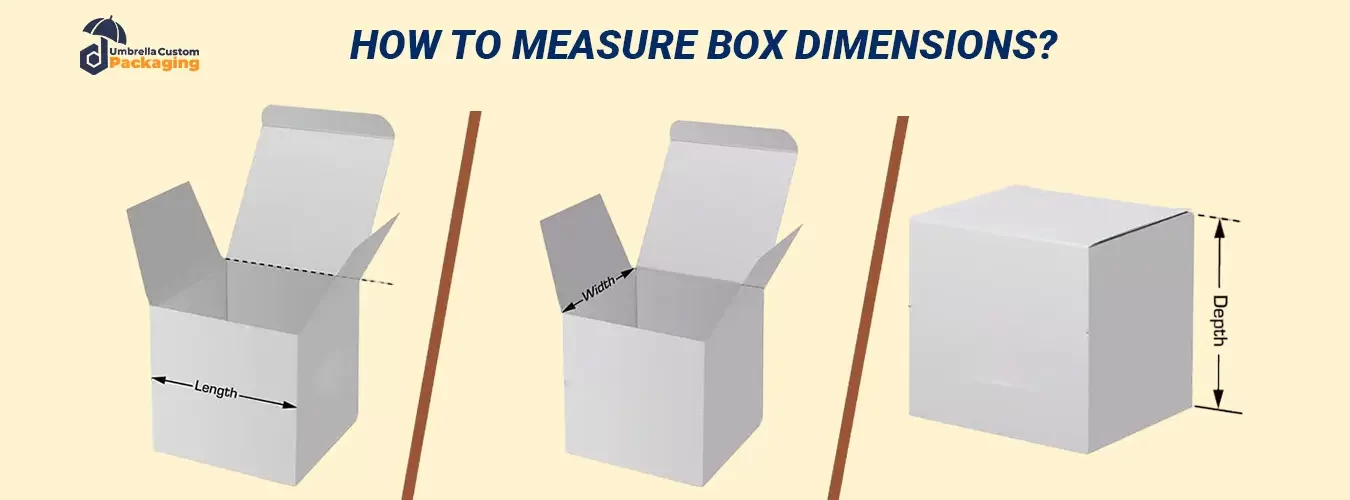

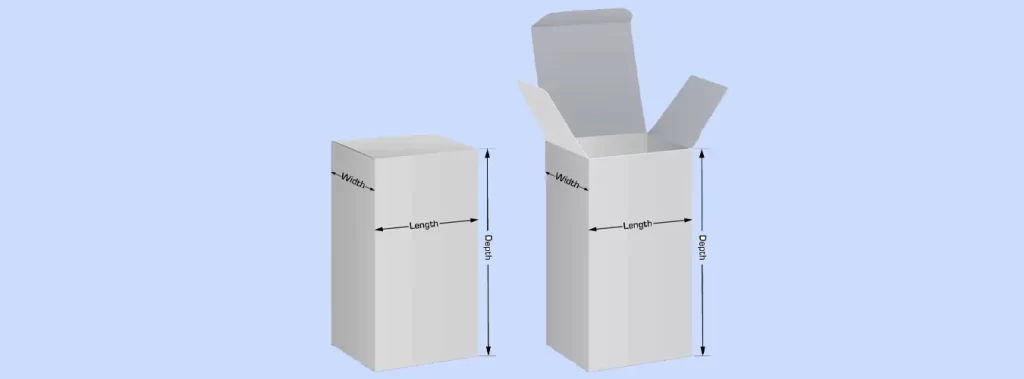

The three dimensions of a box are Length, Width, and Height. These measurements help us figure out how big the box is in every direction.

Step 1: First, understand the dimension

Before you start measuring, it’s important to know what each dimension means.

- Length: This is always the longest side of the box. Think of it as the side that stretches the farthest from one end to the other.

- Width: Next, the width is the shorter side that runs from left to right.

- Height: Finally, the height is how tall the box is. It goes from the bottom up to the top.

Step 2: Next, grab a measuring tool

After you understand the dimensions, you need a tool to measure the box. You can use a ruler or a measuring tape. Make sure your tool is long enough to measure the longest side of the box. Once you’re ready, move to the next step!

Step 3: Then, measure the length

Now, take your measuring tool and find the longest side of the box. Place the tool at one corner and stretch it all the way to the opposite corner. Once you have the measurement, write it down right away, so you don’t forget it.

Step 4: After that, measure the width

Once you’ve measured the length, move on to the width. Look for the shorter side that runs from left to right. Just like before, place your measuring tool at one corner and measure straight to the other corner. Again, write this number down to keep track.

Step 5: Next, measure the height

Now that you’ve measured the length and width, it’s time to measure the height. Turn your attention to the vertical side of the box. Start at the bottom of the box and measure straight up to the top. Be careful to keep your measuring tool straight. Once you’re done, write this measurement down too.

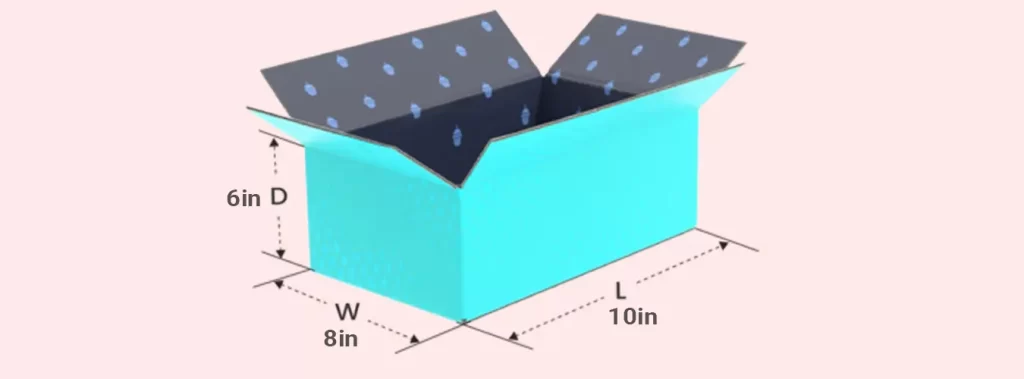

Step 6: Finally, write the dimensions in order

At this point, you have all three measurements! To finish, always write them in the same order: Length × Width × Height. For example, if the box is 10 inches long, 8 inches wide, and 6 inches tall, you write it as 10’’× 8’’ × 6’’.

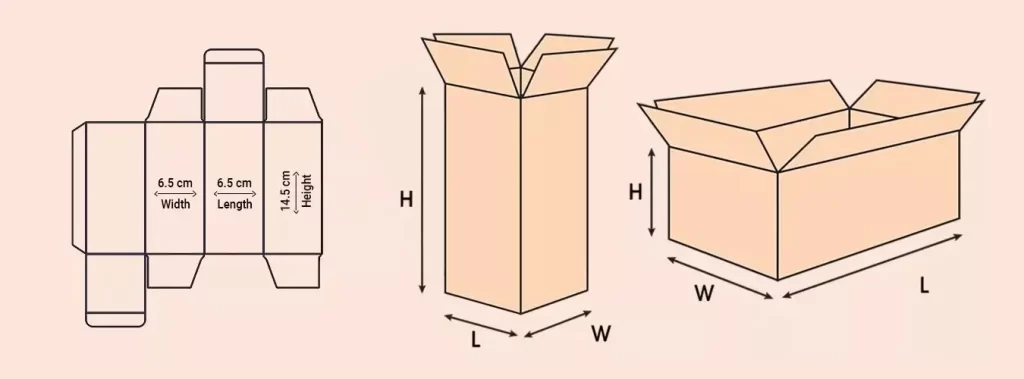

For a tall or upward-facing box, the depth becomes the most noticeable dimension, while the length and width are comparatively smaller.

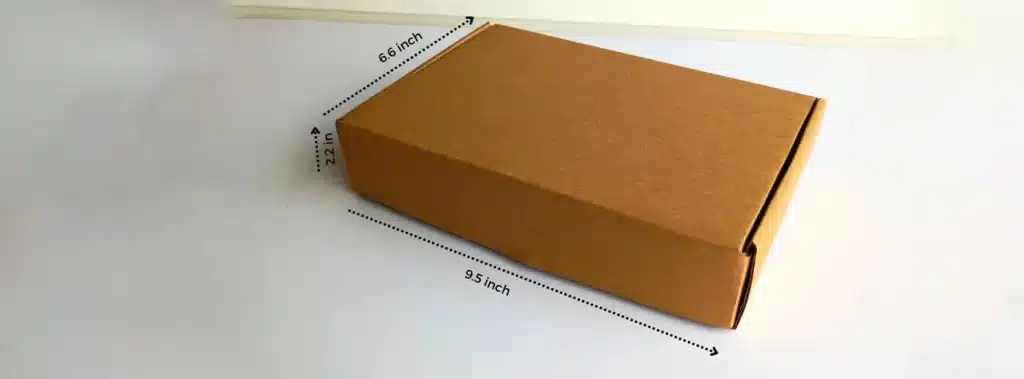

As shown below, the depth and width of long boxes are significantly smaller compared to their length.

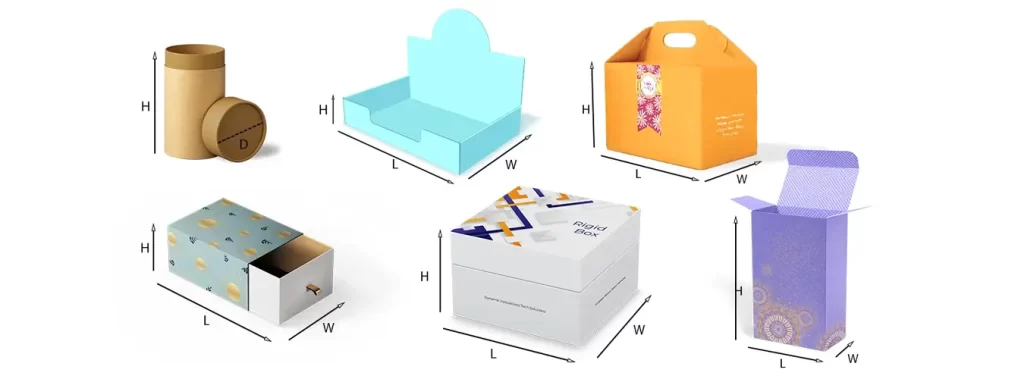

Different types of boxes i.e. rigid, display, cubic, cylindrical, drawer, and gable boxes have different dimensions.

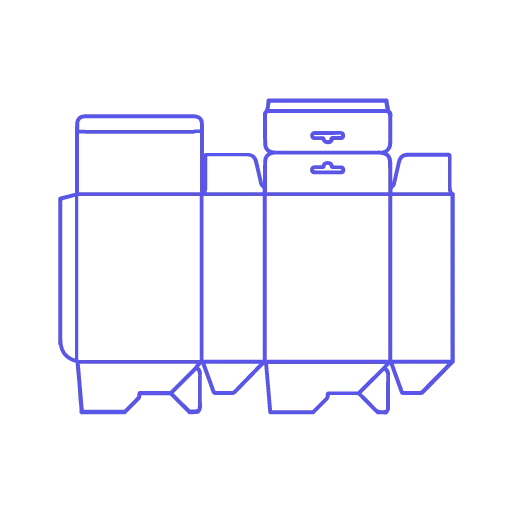

Difference between External and Internal Dimensions of a Box

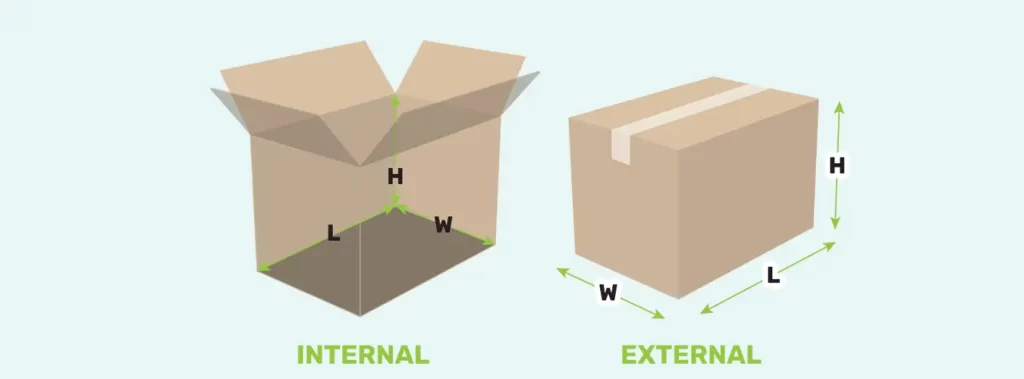

When we talk about a box, it’s important to understand the difference between external dimensions and internal dimensions. To begin with, external dimensions refer to the measurements of the outside of the box. These include the total length, width, and height, which you measure from one outer edge to the opposite outer edge.

In addition to this, external dimensions are especially important because they show how much space the box will take up during shipping, stacking, or storage. For example, if you need to fit the box into a truck, on a shelf, or in a specific space, you’ll rely on these external measurements to plan accordingly.

On the other hand, internal dimensions are all about the inside of the box. Specifically, these measurements tell you how much room is available for your items to fit. To calculate internal dimensions, you’ll measure from one inner edge to the opposite inner edge, and you’ll also need to subtract the thickness of the box material, such as cardboard.

Furthermore, internal dimensions are crucial when you’re deciding whether your product, along with any padding or protective materials, will fit inside the box comfortably. In short, while external dimensions help you understand how much space the box takes up on the outside, internal dimensions focus on the usable space available on the inside.

For a perfect-sized packaging box, you will have to know the exact external and internal dimensions of the box.

How to Measure Dimensions of Cylindrical Objects?

To measure the dimensions of a cylindrical object, start by measuring the diameter of its circular base, which is the distance across the widest part of the base. Then, divide the diameter by 2 to get the radius. Next, measure the height of the cylinder, which is the distance between the two circular bases. After finding these measurements, calculate the volume using the formula:

V=π×radius2×height

For example, if the diameter is 10 cm and the height is 20 cm, the radius will be 5 cm, and the volume will be:

V=π×52×20=π×25×20=1570 cm3

This process helps you quickly and accurately measure cylindrical objects.

Within a Click’s Reach

At Umbrella Custom Packaging, we offer all types of packaging boxes to suit your needs. Whether you are looking for boxes for shipping, storage, or display, we have a wide variety of options available in different shapes, sizes, and styles. No matter what your requirements are, you can count on us to provide the perfect packaging solution.

When you decide to place an order with us, you also get a free quote, which helps you estimate the cost upfront. In addition, there are no hidden charges, and we ensure that our pricing remains transparent and affordable. As a result, you can plan your packaging budget with ease and confidence.

Moreover, we provide expert guidance on box dimensions and sizes. If you’re unsure about the right size or shape for your packaging, our team is here to assist. With our help, you can choose boxes that fit your products perfectly, ensuring both protection and professionalism. So, don’t wait. Order now, and let us take care of the rest!