Foil stamping printing is a special way of adding shiny, colorful designs to paper or other materials. It uses a metal foil and a special machine that presses the foil onto the surface of a product, like a card or a box. This technique makes the designs look shiny, bright, and eye-catching. It’s often used for things like fancy invitations, business cards, packaging, and even book covers.

It is like adding a shiny sticker, but instead of using a regular sticker, it uses a shiny metal that sticks perfectly to the paper when pressed with heat. The result is a beautiful, glossy, and eye-catching design

Key Techniques of Foil Stamping

There are several important techniques. Let’s look at each one to understand how they work:

Cold Foil Stamping:

Cold foil stamping works differently. Instead of using heat, it uses an adhesive that sticks to the material. Then, the machine presses the foil onto the adhesive. This method is often faster and works on a wider range of materials.

Embossing and Debossing with Foil:

Sometimes, the foil is combined with embossing or debossing. Embossing makes a design raised above the surface, while debossing makes a design sink into the surface. When foil is added to these designs, it makes the raised or sunken parts shiny and even more eye-catching.

Multi-Color Foil Stamping:

In some cases, you can use more than one color of foil. The process involves applying different layers of foil, one at a time, to create designs with more than one color. This can make the design even more colorful and exciting.

Spot Foiling:

This technique is used to highlight specific areas of a design. For example, if you have a business card, you might only put foil on the company’s logo, making it pop out while the rest of the card remains simple.

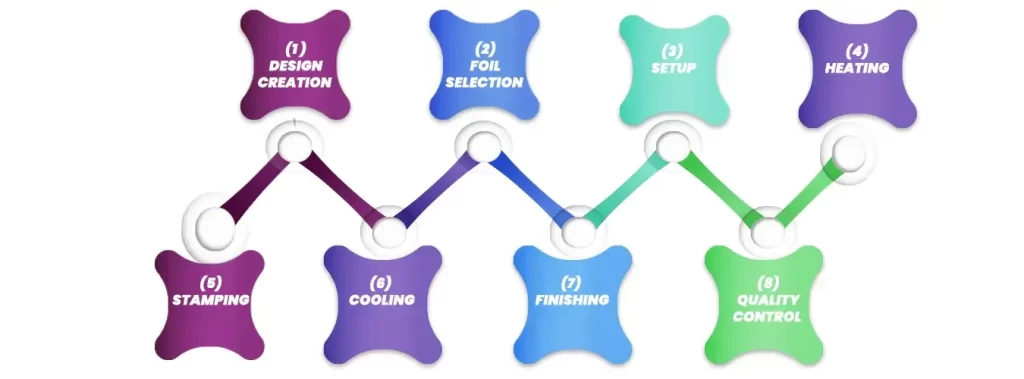

Hot Foil Stamping Process

Hot foil stamping is a technique used to apply metallic or pigmented foil onto surfaces for decorative purposes, thereby enhancing products like packaging, cards, and labels. First, we create a design and convert it into a stamping plate (die). Next, we select the foil based on the desired finish and load it into the machine.

Then, heat the die, which activates the adhesive on the foil. Afterward, heat and pressure transfer the foil onto the substrate, followed by a cooling phase to set the foil. Subsequently, further processing like cutting or embossing may occur.

Finally, the product undergoes quality control to ensure accuracy and eliminate defects. As a result, this process provides a premium, visually striking finish often used in branding and luxury items.

Design & Trends in Foil Stamping

Designs in foil stamping can be as simple or as complex as you like. Recently, there has been a rise in combining foil stamping with modern design trends. Here are a few design trends:

- Minimalistic Design: Sometimes, less is more. Designers are using it in simple, clean ways. A small logo or a few letters can be made shiny, creating a sleek and elegant look.

- Floral and Nature Patterns: Some designs use it to bring out nature-inspired patterns, such as flowers or leaves. These designs look beautiful when the foil catches the light and shines.

- Geometric Shapes: Geometric patterns, like triangles or squares, are popular in modern foil stamping. These patterns can look very striking, especially when paired with bold colors.

- Retro and Vintage Styles: Another popular trend is using it for vintage or retro designs. The shiny foil makes old-fashioned styles look fresh and new, while still keeping that classic charm.

Benefits of Foil Stamping Printing

It has many advantages that make it a popular choice for designers and businesses.

Visually Stunning:

The biggest benefit is that it makes designs look shiny and special. The metallic finish catches the light and makes the design stand out, which is perfect for attracting attention.

Luxurious Feel:

Foil stamping gives any item a high-end, luxurious feel, which is why people often use it for fancy invitations, premium cards, or expensive product packaging.

Durability:

Unlike some other printing methods, it is very durable. The foil doesn’t easily fade or scratch off, so your design stays looking beautiful for a long time.

Versatile:

You can use it on many types of materials, such as paper, plastic, fabric, and more. A very flexible technique can work for many different kinds of projects.

Quick and Efficient:

Once the setup is done, it can be very fast. You can produce high-quality prints quickly, which is useful for businesses that need to create many copies of something.

Applications of Foil Stamping Across Different Industries

Here’s a simple table outlining the applications of foil stamping across various industries:

| Industry | Applications |

|---|---|

| Packaging | Used for adding metallic or glossy finishes on product packaging, enhancing its visual appeal and making products stand out on shelves. |

| Printing | Enhances business cards, brochures, invitations, and catalogs with shiny or metallic designs. |

| Fashion & Textiles | Applied to fabrics for decorative designs on clothing, accessories, and footwear. |

| Pharmaceuticals | Printed foil labels for medicine packaging to indicate authenticity or important details. |

| Cosmetics | Foil stamping on cosmetic packaging for a luxurious and high-end appeal (e.g., perfume bottles, makeup boxes). |

| Electronics | Used for branding and logos on electronic devices (e.g., mobile phones, laptops). |

| Gift & Stationery | Applied to greeting cards, gift wrapping, and premium stationery for added elegance. |

| Promotional Items | Used in promotional products (e.g., custom gifts, awards, souvenirs) for a shiny, attractive finish. |

Choosing the Right Foil Stamping Technique

Choosing the right technique for foil stamping depends on what you need for your project. Here are a few things to think about:

Material: First, make sure the foil stamping technique you choose works well with the material you are using. Not all materials are good for all types of foil stamping.

Design: Additionally, some designs may need special techniques like embossing or multi-color foil stamping to look their best.

Budget: Lastly, some techniques, like cold foil stamping or multi-color foil, might cost more. Consider your budget and choose a technique that fits.

Advantages and Disadvantages of Foil Stamping

Advantages:

Firstly, it provides a high-quality finish, giving products a shiny, metallic, or glossy effect that makes them look more premium. Additionally, it allows for attractive designs, making it ideal for intricate patterns, logos, and text. Moreover, the foil is durable, resistant to wear and tear, and ensures a longer-lasting finish.

What’s more, it requires no ink, which can be more environmentally friendly compared to other printing processes. Furthermore, it is versatile, as it can be applied to various surfaces like packaging, greeting cards, and book covers. As a result, foil stamping helps in enhancing branding, giving products a premium appearance that stands out and attracts attention.

Disadvantages:

On the downside, it comes with an expensive setup cost due to the initial investment in dies and machine setup. However, it is limited to certain substrates, working best on materials like paper and plastic. In contrast, the foil comes in a limited color range, with most foils being metallic, which may not suit all design needs.

Nevertheless, the process is complex, requiring precise alignment, and errors can occur if not set up properly. That said, foil stamping is not suitable for large areas, as it is more effective for small, detailed designs rather than covering broad surfaces. Finally, the process can be time-consuming, especially when handling complex designs, making it slower than some other printing methods.

Conclusion

Foil stamping is a fun and creative way to make designs stand out. Whether you’re designing a fancy invitation, a shiny business card, or a beautiful book cover, foil stamping adds a touch of elegance and luxury to your project. By using the right techniques, materials, and designs, you can make your work look professional and eye-catching. Just remember to consider the materials, the design, and the budget, and you’ll create something truly special.

At Umbrella Custom Packaging, we often work with a variety of items and foil stamping in custom packaging. In addition to helping keep products safe during shipping and storage, custom packaging also enhances the overall appearance of your product. The design fits each item perfectly, ensuring that it prevents damage or loss of shape.

If you are looking for custom packaging for your products, feel free to contact us. We will help you find the best packaging solution for your items, protecting them while also making them look attractive.